In a few years, a traditionally low-tech, complex industry like farming can open a variety of applications to the global chain.

The massive impact that COVID-19 has made on the global food system requires a close review- indeed, it is highly probable that we will soon face some fundamental problems, which we will not be able to ignore anymore.

Bloomberg reports the following: “France expects some 200,000 workers will fail to show up this year. Coldiretti, an association of Italian farmers, estimates the country will be short as many as 100,000 foreign laborers. Germany typically has 30,000 migrant farm workers in March and 80,000 by May, but this year, only a fraction of that number have shown up, according to Agriculture Minister Julia Kloeckner.”

The Agricultural Outlook 2018-2027 published by the Food and Agriculture Organization (FAO) of the United Nations states that of the total land area of the MENA region, only one-third is agricultural land (cropland and pastures), while only 5% is arable (cropland). The rest of the land is either urban or dry desert. Due to the dry climate, about 40% of cropped area in the region requires irrigation. Only 4% of land in the region has soils judged of high or good suitability for rain-fed cereal cultivation and 55% is unsuitable. This means a strong dependency on import, not just from Europe but from other main export countries like India, for example, one of the larger fruits and vegetable supplier for the Middle East.

However, according to Mumbai Mirror, because if the cancellation of flights to Europe and Middle East due to COVID-19, fruits and vegetable exporters in Mumbai have reported 25% drop in business. But, at the same time, even when the flights became operational, the charges have gone up by two-and-a-half times. Taking the sea route isn’t a feasible option either due to prohibitive costs. Moreover, for countries whose share of total merchandise export earnings spent on food imports is high and volatile, like the Middle East, the stability of international food prices is a major concern. Even if export earnings can be maintained, these countries face significant risks associated with spikes in world food prices.

According to the UAE Ministry of Economy, in 2015, Dubai imported about 11 thousand tonnes of fruits and vegetables per day, of which 30% to 40% where re-exported to many of the neighbouring countries in the region. According to Khaleej Times, in 2019, the UAE imported 80% of its food, which is a major challenge also for the country’s food security. Similar figures were also disclosed by Saudi Arabia: according to FoodExport, the Kingdom depends on imports to meet about 75% of its food needs.

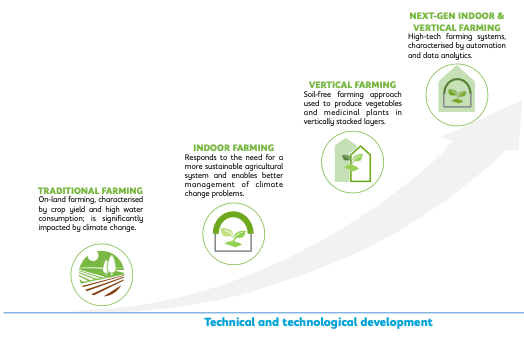

Given these figures, it is fundamental for Middle East countries to find a way to become autonomous on the food production front, especially on the categories generating a higher productivity per drop of water, like fruits and vegetables. So, what are the answers? Well, the evolution of food tech can be one. Driving forces shifting the interest in food tech include the spread of pandemics, climate change, population growth, digitalization opportunities, as well as organic food consumption, and health-focused consumers. Indeed, in a few years, a traditionally low-tech, complex industry like farming can open a variety of applications to the global chain.

The foodtech and agtech startup industry raised nearly US$20 billion in 2019, a 250% increase over five years, according to a new report from venture capital firm AgFunder, one of the world’s most active foodtech and agtech VCs. In terms of sectors, vertical farming is one of the categories where VCs and visionary investors are focused on, as evidenced by these examples:

- 2017: Softbank invests $200 million in silicon valley startup Plenty;

- 2017: IKEA and the Ruler of Dubai, H.H Sheikh Mohammed bin Rashid Al Maktoum, invest $40 million in AeroFarms (with $115 million invested in the company over its life)

- 2018: Google Ventures invests $90 million in Bowery Farming

- 2019: Ocado, a British online grocery retailer, invests over $20 million to grow leafy greens and herbs next to its distribution centers through indoor farming.

According to a set of reports published by Allied Market Research, titled, Vertical Farming Market by Component, Structure, and Growth Mechanism, the global vertical farming market size was $2,23 billion in 2018, and it is projected to reach $20 billion by 2026, growing at a CAGR of 24.6% from 2019 to 2026. Depending on growth mechanism, the market is sub-segmented into hydroponics, aeroponics, and aquaponics. The hydroponics segment contributed nearly 40% of the share in 2018.

Vertical farming is expected to become an enhanced substitute of traditional farming, as it produces 70% more crop and uses almost 90% less water as compared to the traditional farming. Over the last years, the technology has incredibly evolved- vertical farming increased its business model efficiency bringing to life a full ecosystem showing significant benefits to the vale chain, which include:

- Higher cultivation yield thanks to 24/7 operations and faster crop cycles, lower pre/post-harvest waste and high indoor-outdoor acre equivalent

- Optimal environmental and other input controlleading to higher yields and better crop quality (both in terms of flavour and nutrition)

- Lower water usage (reduction ~ 90%-99%) and chemical use (leading to economic, health and environmental benefits)

- All-year-round production with shorter supply chain (leading to fresher products and lower transportation costs)

- Higher transparency and traceability of products

- Lower risks affecting yields, profitability (i.e., weather, pests, pathogens, and weeds), and therefore, lower insurance policy costs

The rise of technology driven autonomous ecosystems was more clearly explained to me when I interviewed Thomas Ambrosi, CEO of ONO Exponential Farming, an innovative startup active in the agri-technology sector, focused on high-tech vertical farming solutions. Thomas explained that his startup’s business model is not simply based on delivering a farm infrastructure, but instead a real ecosystem: it’s a platform where mechanics, robotics, information technology, artificial intelligence (AI), machine learning, virtual reality, and an agronomic knowledge base are mixed together in order to allow anyone to grow anything, anywhere. The ONO Exponential Farming business model itself is focused on delivering the most advanced robotic solutions possible to help agriculture to move forward, based on cloud-driven machineries.

The company has patented a scalable and modular vertical farming platform which is fully automated, and which can be used for the intense cultivation of vegetables, algae, and insects. The automation is based on robotics and software with machine learning and AI systems. According to ONO Exponential Farming, the level of productivity is incredible: for lettuce, for example, the productivity per square meter is about 8,000%, versus the open field farming, and 241% versus the vertical farms concepts developed some years ago. In addition, the solution is showing high level of sustainability, saving about 70% of consumption per kw/ton versus traditional vertical farms. ONO Exponential Farming also uses innovative automation technology to eliminate the last existing contaminant in the production process: human presence.

Some Middle East Countries (or rather, cities) have already made some interesting plans in this particular domain. Dubai Industrial City is where Badia Farms is planning to launch a new high-tech vertical farmin Q2-2020 to contribute to the UAE’s commitment to becoming more sustainable, especially since hydroponic technology is expected to be a major contributor to agricultural sustainability and food diversity, as it improves crop production and lowers its cost. The facility will have the capacity to produce 3,500kg of high-quality fruits and vegetables on a daily basis, which begs the question: will those volumes be enough for balancing the scarcity of fruits and vegetables supply from the major exporting countries?

In Saudi Arabia, agriculture accounts for 85% of the water consumption in the country. Most of the water utilized for the cultivation of fruits and vegetables is drawn from ground water resources and desalination plants. Water from these plants is highly subsidized; hence, the government plans to diversify the type of crops grown in the region to those that consume less water. This initiative is also supporting the realization of Vision 2030, given that the Kingdom aims to become one of the major touristic destinations in MENA by then, and as such, food supply will surely represent a significant challenge.

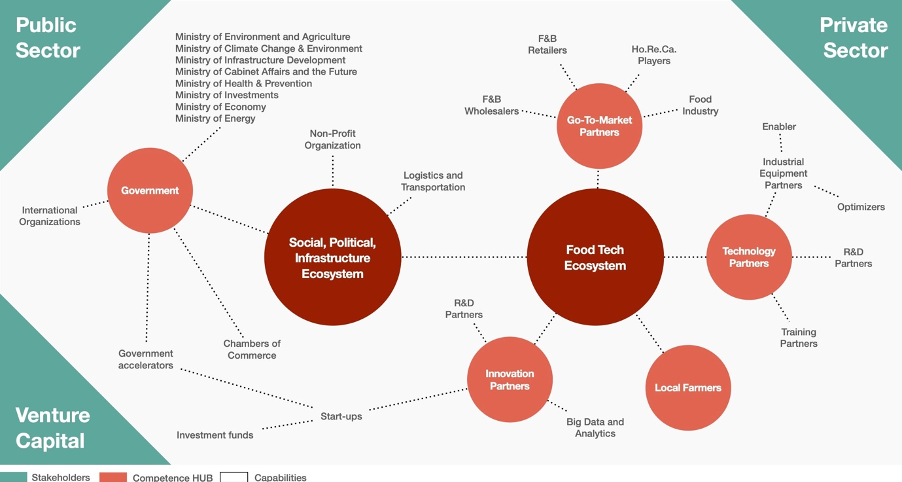

With all this said, what is the opportunity here for the Middle East? The food supply issue is both a short-term and long-term challenge: building up ecosystems of capabilities by partnering with startups, researchers, technology providers, agricultural experts, innovators, can be –once again- the answer to the urgent need of becoming more autonomous by offering sustainable and safe solutions to the market.

Food security primarily relies on availability, accessibility, and affordability of food, which can easily be achieved by means of vertical farming. With technological advancements, vertical farming in supermarket and retail centers will positively augment growth in the industry, which will not only reduce the transportation time and cost, but will also minimize the chances of spoilage.

The scarcity of domestic production resources and dependence on third parties has highlighted the urgent necessity for innovative, cost-effective, and automated technological solutions in the food production process. On the global scene, the indoor farming innovation is attracting great interest for the opportunity to guarantee results in terms both of quantity and quality, and many initiatives have been launched to find the most effective technological and operational solutions. The emergency produced by the COVID-19 pandemic has also underlined the need to reduce reliance on the human presence in the food production process, and it’s also made the fact clear that robotized automation is no longer an alternative, but a necessity.

Entrepreneur / Balkantimes.press

Napomena o autorskim pravima: Dozvoljeno preuzimanje sadržaja isključivo uz navođenje linka prema stranici našeg portala sa koje je sadržaj preuzet. Stavovi izraženi u ovom tekstu autorovi su i ne odražavaju nužno uredničku politiku The Balkantimes Press.

Copyright Notice: It is allowed to download the content only by providing a link to the page of our portal from which the content was downloaded. The views expressed in this text are those of the authors and do not necessarily reflect the editorial policies of The Balkantimes Press.